April 1, 2023

9 Reasons Why Professional Tube Bending Is Essential for Industrial Projects

Team Pipe Processing

*Edited for clarity and additional data on January 2025.

Introduction

For various industrial applications, pipes and tubing are bent into specific shapes and configurations through the process of tube bending. The material is heated to a specific temperature and bent into the desired shape using a machine during the process. In many industries, including aerospace, automotive, construction, and manufacturing, tube bending is a crucial step. The success of these industries depends on their ability to shape and arrange pipes and tubing in particular ways.

The importance of tube bending in industrial projects cannot be overstated. The process is essential for the creation of complex structures that require precise measurements and configurations. Tubes and pipes are used extensively in industrial applications, including manufacturing, transportation, and construction. tube bending allows for the creation of customized products that meet the specific requirements of each application.

The goal of this article is to provide the reasons why professional tube bending is essential for industrial projects. Now let us invade each area on why professional tube bending Is essential for industrial projects.

1. Accuracy and Precision

Accurate tube bending is essential for ensuring components fit properly and systems function reliably. In industries like aerospace and automotive, even minor errors can lead to safety risks or reduced performance, making precision a non-negotiable requirement.

Why Precision in Tube Bending is Critical for Industrial Success

Precision is critical across industries that demand high safety and reliability standards. Advanced tools and skilled professionals ensure that tubes and pipes are bent to exact specifications, meeting strict requirements.

Key Benefits:

- Guarantees proper fit and seamless functionality.

- Reduces the risk of safety hazards and system failures.

- Meets industry-specific performance standards.

Industry Applications:

- Aerospace: In aerospace, accurate tube bending is crucial for the safe operation of fuel and hydraulic systems. Any small error in bending can lead to system malfunctions, compromising safety.

- Automotive: The automotive industry requires precise tube bending for components like chassis, suspension, and exhaust systems. Accurate bends ensure these systems perform optimally and meet safety standards.

- Healthcare: In healthcare, medical devices depend on accurate tube bending to ensure reliability and functionality. Misalignment can lead to device failures, affecting patient safety.

Professional tube bending delivers the accuracy and precision essential for high-stakes industries. By combining advanced technology and expert knowledge, it ensures safety, reliability, and optimal system performance.

2. Quality Control

Quality control is essential in industrial applications, particularly those requiring precision and accuracy. It ensures that products meet necessary reliability and quality standards. Industries like aerospace, automotive, and healthcare demand the highest level of attention to detail, as even small defects in the final product can lead to serious safety risks. Quality control processes employ various tools, techniques, and technologies to measure and confirm that the product meets required specifications.

Why Quality Control is Crucial for Tube Bending

Industrial tube bending projects require professional expertise to ensure that the tubes and pipes meet precise specifications. Expert tube bending companies possess the knowledge, experience, and advanced technology needed for accurate results. They use cutting-edge bending equipment to measure angles and degrees, ensuring that the final product adheres to exact requirements.

Key Benefits:

- Ensures products meet required standards for reliability and quality.

- Reduces the risk of product failure and increases customer satisfaction.

- Prevents costly rework and repairs by identifying issues early.

Advantages of Quality Control in Industrial Projects

Quality control has multiple advantages, including ensuring that the finished product meets all reliability and quality requirements. This leads to higher customer satisfaction and reduced failure rates. Additionally, quality control helps reduce costs and waste by preventing errors that require rework or repairs. By detecting flaws early in the process, quality control minimizes the risk of product failure and lowers repair expenses.

Quality control plays a pivotal role in tube bending for industrial applications. Professional tube bending companies employ rigorous quality control procedures to ensure products meet the highest standards of precision and reliability, benefiting both performance and cost-efficiency.

3. Time and Cost Savings

Time and cost efficiency are critical components of successful industrial projects. Completing tasks on schedule and within budget requires careful planning, execution, and management. For any industrial venture to remain competitive and profitable, saving time and money is essential.

How Professional Tube Bending Saves Time and Costs

Professional tube bending offers precise angular and radial bending using advanced equipment and technology. This process reduces the need for manual labor, minimizes waste, and ensures accurate results. By eliminating errors and rework, industries can save both time and material costs.

Key Advantages of Professional Tube Bending:

- Reduces manual labor, saving valuable time.

- Minimizes material waste, lowering overall costs.

- Improves accuracy, preventing costly errors and rework.

- Shortens project timelines, enabling faster completion.

By reducing project timelines and costs, industries can allocate resources to new ventures and innovations. Professional tube bending ensures tasks are completed efficiently, allowing companies to remain competitive while focusing on future growth.

Professional tube bending streamlines industrial projects by saving time and reducing costs. Its precision and efficiency not only improve current operations but also pave the way for future opportunities and profitability.

4. Safety

Safety is a fundamental concern in any industry. Industrial projects often involve heavy equipment, hazardous materials, and high-risk activities, making precautions essential to protect workers, clients, and the environment. Without proper safety measures, accidents can lead to severe injuries, property damage, or environmental harm.

How Professional Tube Bending Enhances Safety

Expert tube bending is a critical component of industrial projects requiring tubes and pipes. Using advanced technologies like Computer Numerical Control (CNC) machines ensures precise and reliable results, which contribute to the safety and durability of the final product.

Benefits of Safety-Focused Tube Bending:

- Ensures the reliability of components under high-pressure and high-temperature conditions.

- Reduces the risk of accidents caused by flawed or improperly bent tubes.

- Meets industry safety standards for critical applications.

Safety Across Key Industries

Safety is paramount in industries such as aerospace and automotive:

- Aerospace: Tubes and pipes used in aircraft must meet stringent safety standards. Even minor flaws can have catastrophic consequences. Professional tube bending ensures these components are durable, reliable, and meet quality requirements.

- Automotive: Tubes in vehicles must withstand pressure, vibration, and temperature changes. Professional tube bending guarantees that these parts perform safely under extreme conditions, contributing to vehicle reliability.

Pro Tip: Professional tube bending not only delivers high-quality results but also prevents fatal accidents, ensuring a safe and sustainable industrial environment.

Safety is a non-negotiable priority in industrial projects. Professional tube bending plays a crucial role in meeting safety standards, protecting lives, and ensuring the durability of components across various industries.

5. Versatility

Tube bending is a versatile manufacturing process widely used across various industries. Its flexibility lies in the ability to create curved or angled shapes in different radii, lengths, and configurations. This adaptability makes tube bending essential for producing complex parts and components in sectors like automotive, aerospace, construction, and medical.

Why Versatility Matters

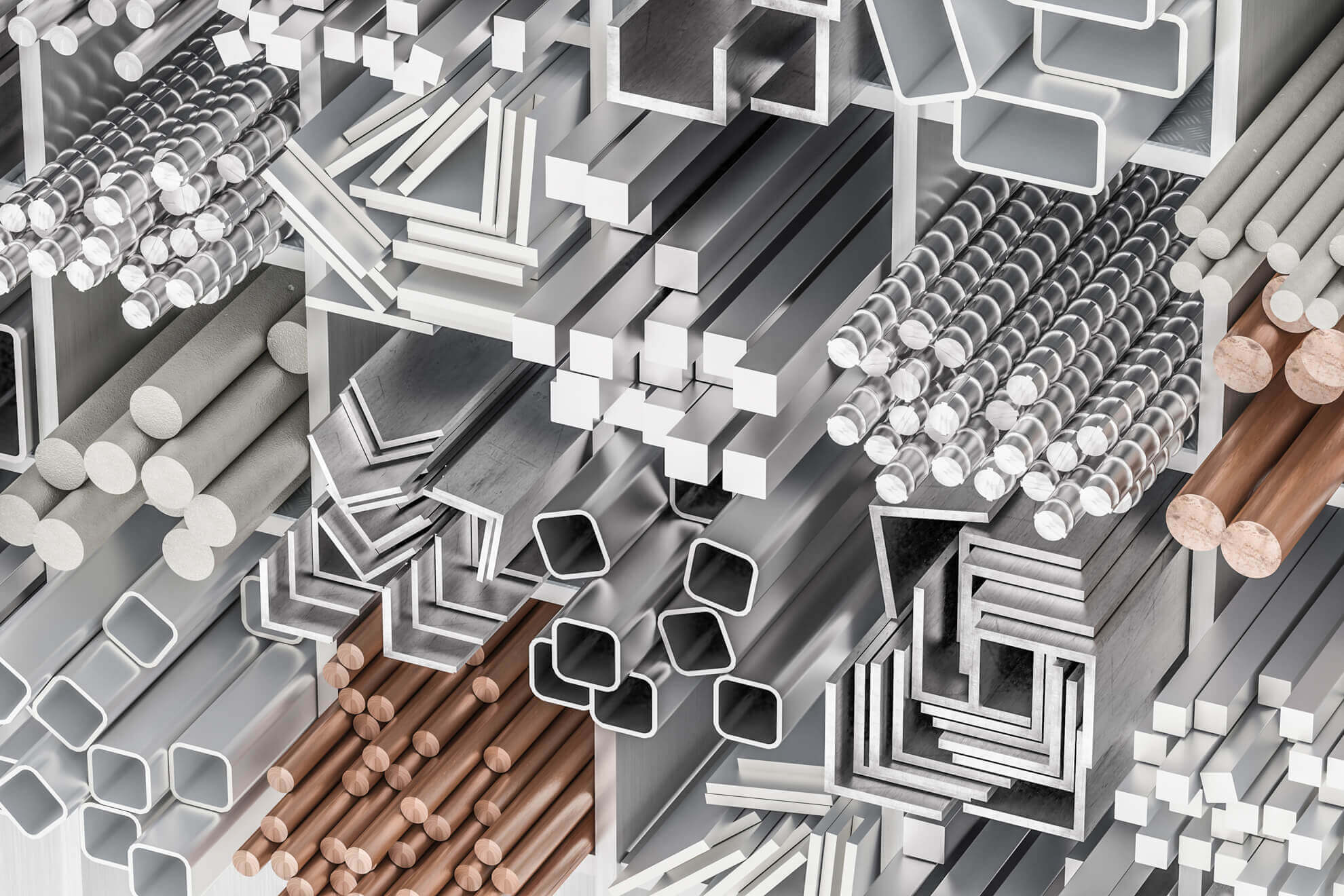

Professional tube bending companies provide tailored solutions to meet the diverse needs of industrial projects. They work with a wide range of materials, including brass, aluminum, stainless steel, and copper, offering unmatched customization options. This flexibility ensures components are designed to meet specific project requirements with precision.

Applications Across Industries

- Automotive: Tube bending is vital for manufacturing components like exhaust systems, fuel lines, and brake lines, ensuring performance and durability.

- Aerospace: From hydraulic systems to airframe components, tube bending supports the precise engineering required for aircraft.

- Construction: Architectural features such as handrails, staircases, and structural elements rely on tube bending for aesthetic and functional designs.

- Medical: Tube bending is crucial in creating surgical instruments and medical devices, offering precision and reliability for healthcare applications.

The versatility of tube bending makes it a cornerstone of modern manufacturing. Its ability to adapt to the unique needs of various industries ensures efficient, reliable, and innovative solutions for even the most complex projects.

6. Material Preservation

Efficient use of materials is a critical aspect of industrial projects. Material preservation ensures optimal resource utilization while minimizing waste, directly impacting project costs and sustainability. Given the high cost of materials, adopting strategies to reduce waste is essential for achieving financial and operational success.

How Tube Bending Supports Material Preservation

Professional tube bending plays a significant role in preserving materials. By enabling the use of longer tubes and pipes, it reduces the need for additional joints and connectors. This not only minimizes material waste but also speeds up installation, lowering overall project costs. Additionally, expert tube benders select optimal bending radii to minimize material fatigue and reduce excess usage.

Applications in Key Industries:

- Aerospace: Precision tube bending lightens aircraft components, enhancing fuel efficiency while maintaining structural integrity. Advanced equipment and CAD systems enable the creation of lightweight, high-performance tubing.

- Construction: Reduced material waste and fewer joints contribute to efficient and cost-effective infrastructure projects.

- Automotive: Minimizing material use in fuel lines and exhaust systems ensures durability and cost savings.

Material preservation is not just about reducing costs—it’s about creating sustainable, efficient industrial solutions. Professional tube bending ensures resource efficiency, delivering both environmental and economic benefits across industries.

7. Consistency

One rule that promises growth is consistency. For industrial projects, consistency is essential because it ensures the final product will be of high quality, precise, and reliable. Inconsistencies can result in errors, malfunctions, and safety risks, which waste time and resources, generate lost revenue, and harm a brand's reputation. When it comes to manufacturing, production, or assembly line-related industries, consistency is especially important because even the smallest deviation from the norm can seriously disrupt a workflow.

In many industrial applications, Professional tube bending businesses can use CNC (Computer Numerical Control) machines that are programmed to repeatedly carry out precise bends, ensuring accuracy and uniformity in each product. Using specialized equipment and methods, they measure and confirm the tube's dimensions, angles, and tolerances at each stage of the bending process as well.

For best results, numerous industries need reliable tube bending solutions. Some of them include:

- Aerospace: To meet strict safety and performance standards, aerospace components need tube bending that is precise and consistent. Manufacturing processes for fuel lines, hydraulic systems, and aircraft structures all use tube bending techniques.

- Automotive: Tube bending plays a crucial role in the production of exhaust systems, fuel lines, and brake lines in the automotive sector. Since these parts fit and work correctly thanks to consistent tube bending, the vehicle's overall performance and safety are improved.

- Medical: To create specialized medical devices that meet the needs of each patient, the medical industry needs specialized tube-bending solutions. They produce products like endoscopes, catheters, and stents among others using customized tubes.

8. Customization

Customization is vital in industrial projects to meet specific customer requirements and adapt to unique operational needs. It allows businesses to design products that are tailored for optimal performance, efficiency, and functionality. In a competitive market, offering customized solutions helps companies stand out and address evolving customer demands.

How Tube Bending Enables Customization

Professional tube bending services deliver tailored solutions using advanced tools and technology. CNC (Computer Numerical Control) machines precisely execute client-specific bends, ensuring accuracy and uniformity. Beyond shaping, these services offer value-added options like welding, cutting, and assembly, creating complete solutions designed for individual project requirements.

Benefits Across Industries:

- Automotive: Custom exhaust and fuel systems for optimal performance.

- Aerospace: Tailored hydraulic and airframe components for efficiency and safety.

- Construction: Unique configurations for handrails and structural elements.

Customization in tube bending ensures that industrial projects meet exact specifications while improving performance and market competitiveness.

9. Expertise and Experience

Expertise and experience are foundational to industrial project success. Skilled professionals bring specialized knowledge and practical insights to ensure quality, process efficiency, and safety. Their ability to identify challenges, mitigate risks, and optimize outcomes adds significant value to any project.

Expertise in Tube Bending

Experienced tube-bending professionals guarantee precision and reliability. With in-depth knowledge of materials, equipment, and techniques, they provide solutions that align with client specifications. Their expertise enables accurate bends, uniform results, and optimized processes for diverse applications.

Advantages for Industrial Projects:

- Problem-Solving: Professionals address complex challenges efficiently.

- Consistency: Uniform bends ensure compatibility and performance.

- Risk Mitigation: Experienced teams foresee potential issues, enhancing safety and reliability.

Expertise and experience in tube bending ensure project success by delivering high-quality, efficient, and reliable solutions tailored to industry needs.

Conclusion

To sum up, professional tube bending services are essential for any industrial project, offering promising results and unmatched reliability. By choosing professional tube bending services, you can rest assured that skilled experts will use advanced tools and techniques to deliver precisely constructed tubes that meet the highest standards. For durable and high-quality outcomes, professional tube bending services are the ultimate choice.

Industries face numerous challenges, and outsourcing specialized tasks like tube bending to professionals not only ensures optimal results but also frees up time to focus on other critical operations. We highly recommend utilizing professional tube bending services to maximize efficiency and enjoy significant benefits.

Contact us today to learn how our expert tube bending services can elevate your project!

Share it!

PIPE PROCESSING TECHNICAL INSTITUTE

Streamline Your Pipe Processing Challenges

Streamline Your Pipe Processing Challenges

Struggling with customization complexity, tight deadlines, or rising costs? We deliver:

- Precision bending for custom designs

- Fast turnarounds for tight schedules

- Cost-effective solutions for any scale

Partner with Pipe Processing Technical Institute to streamline your production and overcome challenges with ease.