March 1, 2025

How to Find the Best Pipe Fabrication Company in 2025

Team Pipe Processing

In industries like construction, automotive, and energy, the demand for high-quality, precisely fabricated pipes has never been greater. Whether it's for structural support, fluid transportation, or high-pressure applications, the strength, durability, and accuracy of pipe fabrication directly impact the efficiency and safety of various projects. As businesses aim to reduce material waste and operational costs, selecting a fabrication company that delivers superior craftsmanship has become a crucial decision.

The rapid advancements in technology have transformed the pipe fabrication industry. Modern fabrication companies now integrate CNC machining, robotic automation, and AI-driven quality control to ensure precision and efficiency. IoT-enabled monitoring systems provide real-time feedback, minimizing defects and improving consistency. With sustainability becoming a priority, many fabricators are also adopting eco-friendly materials and energy-efficient processes, making it essential to choose a company that stays ahead of these industry trends.

This guide will help you navigate the process of finding the best pipe fabrication company in 2025. We’ll discuss key evaluation factors, including technological expertise, compliance with industry standards, production efficiency, and customization capabilities. Whether you need pipes for large-scale infrastructure or specialized manufacturing, understanding what sets a reliable fabrication partner apart will ensure you make an informed and cost-effective decision.

1. Defining Your Pipe Fabrication Needs

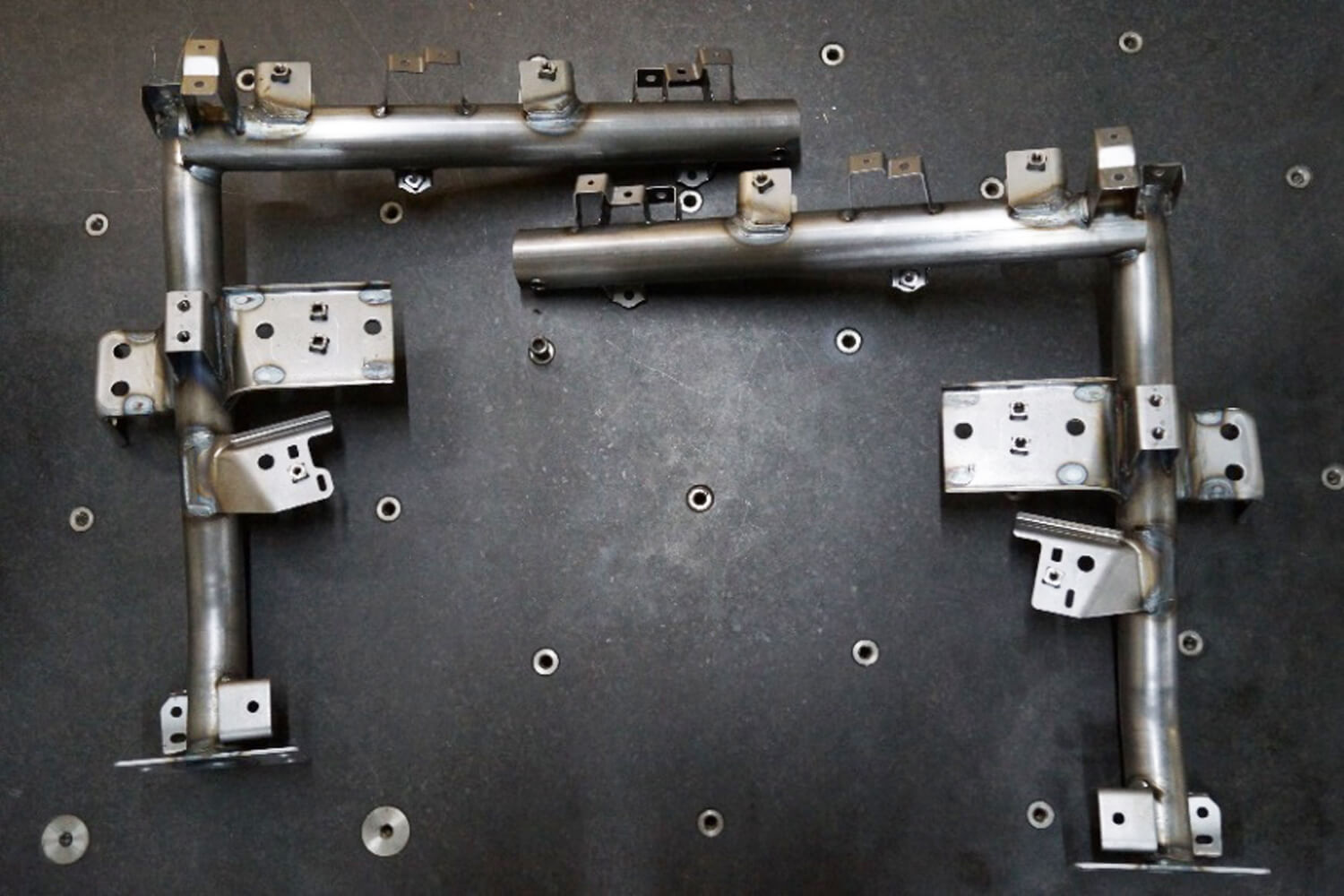

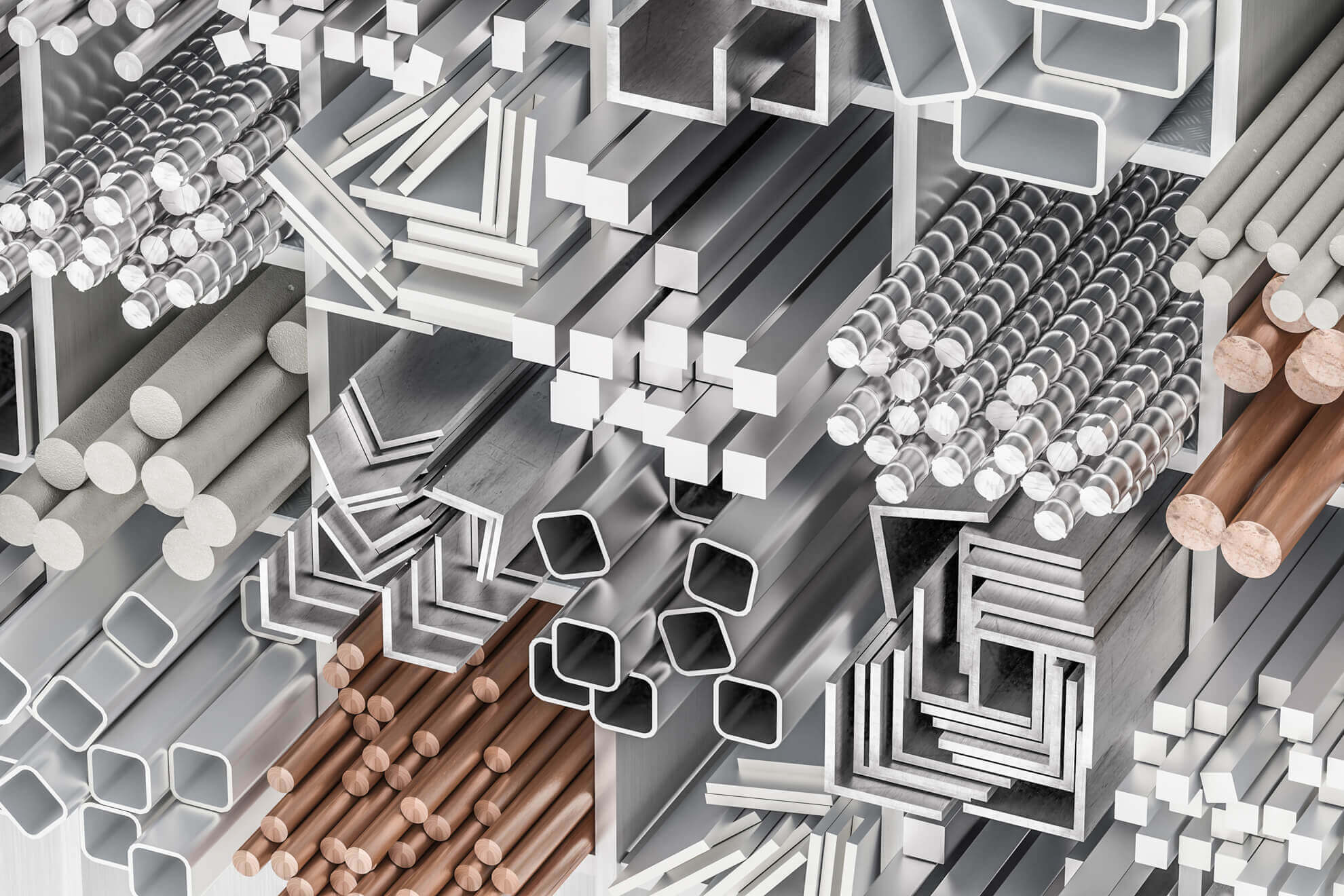

Before selecting a pipe fabrication company, it’s essential to define your project requirements clearly. The type of material needed—whether it’s carbon steel, stainless steel, aluminum, or advanced alloys—affects the fabrication process and final application. Pipe dimensions, including diameter, thickness, and bend complexity, must align with industry standards and intended use. A well-defined scope prevents costly revisions and ensures smooth project execution.

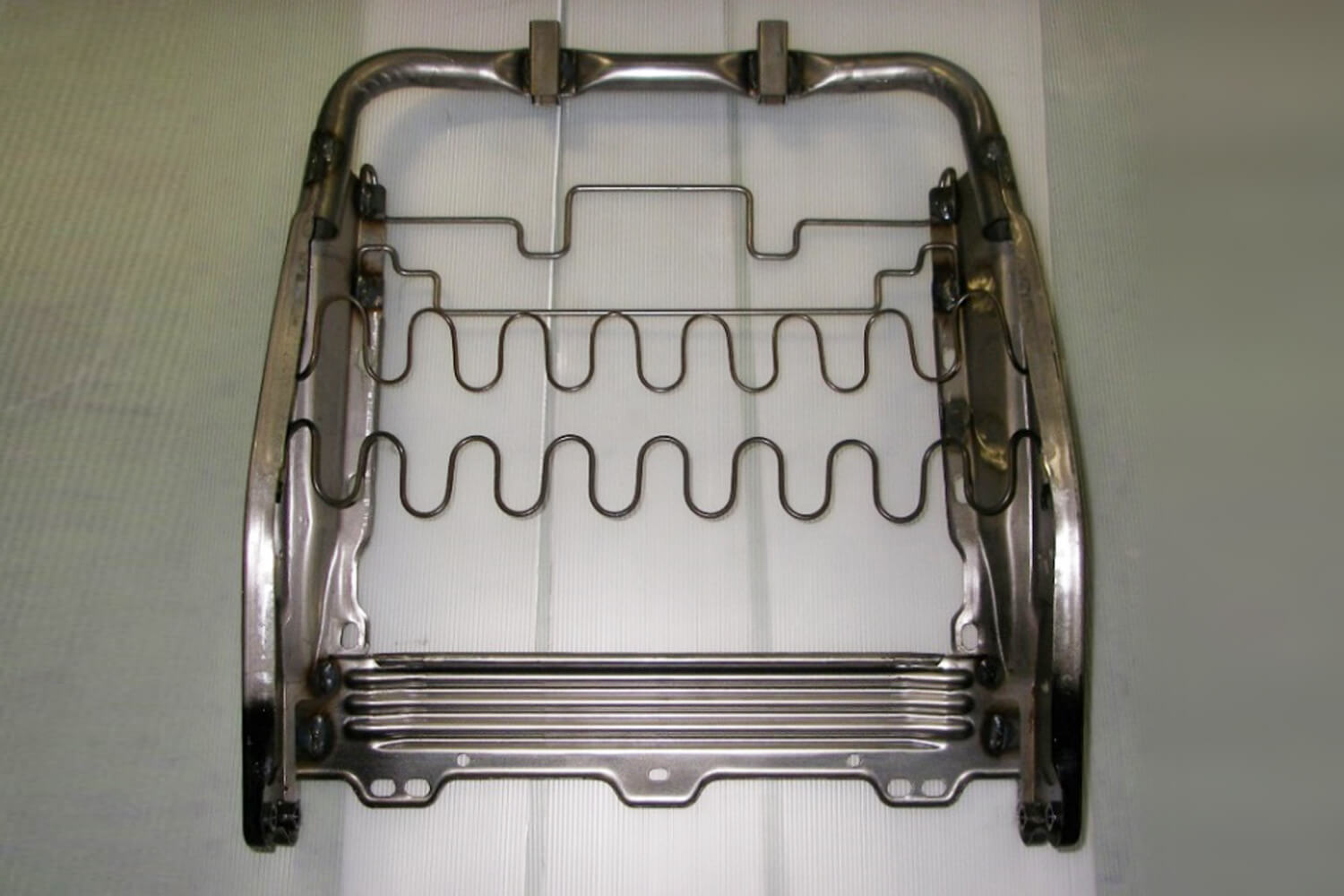

Different industries have specific requirements when it comes to pipe fabrication. The automotive sector, for example, demands lightweight yet durable piping solutions to enhance fuel efficiency, while the aerospace industry relies on high-strength, heat-resistant materials. In energy and construction, pipe integrity and corrosion resistance are critical. Understanding these sector-specific challenges helps in choosing a fabricator with the right expertise.

Selecting a fabrication company that aligns with your project goals is crucial. Look for a provider that not only understands your specifications but also has a track record of delivering similar projects. A good fabrication partner will offer design consultations, suggest material optimizations, and ensure that their processes are tailored to meet your exact needs.

2. Evaluating Industry Experience and Technological Expertise

A company’s experience in the industry speaks volumes about its reliability and capability. A well-established fabrication company with years of specialized experience is more likely to understand industry challenges, adhere to regulations, and deliver consistent results. Specialization in certain types of fabrication, such as precision bending for aerospace or heavy-duty piping for industrial applications, can make a significant difference in project quality.

In 2025, advanced manufacturing technologies are redefining pipe fabrication. Companies utilizing CNC (Computer Numerical Control) machining ensure high precision and repeatability in production. Robotic automation improves speed and reduces human error, while AI-powered fabrication software enhances quality control by predicting stress points and optimizing material usage. Choosing a company that invests in these technologies guarantees superior workmanship and efficiency.

Examining a company’s past projects through case studies can provide valuable insights. Look for real-world applications of their work, success stories from different industries, and the complexity of projects they have handled. Companies that showcase documented results and client testimonials demonstrate their expertise and reliability.

3. Checking Certifications and Compliance with 2025 Standards

Certifications validate a company’s adherence to industry best practices and quality standards. Reputable pipe fabrication companies hold certifications such as ASME (American Society of Mechanical Engineers) for pressure piping, ISO 9001 for quality management, and AWS (American Welding Society) for welding excellence. These accreditations indicate that the company meets global standards for safety, durability, and precision.

Beyond standard certifications, compliance with environmental and safety regulations is equally important. With growing emphasis on sustainability in manufacturing, fabrication companies must follow eco-friendly practices, such as reducing emissions and implementing waste management systems. Safety certifications ensure that workplace hazards are minimized and employees follow strict operational protocols.

Traceability is another critical factor. A company that maintains detailed records of material origins, fabrication processes, and quality checks ensures accountability at every stage. This is particularly crucial for industries like aerospace, energy, and healthcare, where regulatory compliance is strictly monitored.

4. Assessing the Use of Advanced Fabrication Equipment

The right equipment can significantly impact the quality and efficiency of pipe fabrication. CNC pipe bending machines, for instance, allow for high-precision bends with minimal deformation, making them ideal for complex applications. AI-powered quality control systems detect defects in real time, reducing material wastage and ensuring consistency across batches.

Industry 4.0 technologies, such as IoT-enabled monitoring and digital twins, have revolutionized fabrication processes. These innovations provide live data on machine performance, material stress levels, and production efficiency, allowing companies to make adjustments instantly. Investing in a fabricator that embraces these technologies translates into better accuracy and cost savings for your project.

Precision-driven fabrication is particularly essential in industries requiring tight tolerances, such as aerospace and medical manufacturing. By selecting a company equipped with the latest fabrication tools, you ensure that your components meet the highest performance and safety standards.

5. Reviewing Customization and Material Capabilities

Customization plays a vital role in pipe fabrication, especially for industries that require unique configurations or non-standard materials. A top-tier fabrication company should offer tailored solutions, including specialized bending techniques, custom welding, and prototype development. This ensures that each project receives attention to detail rather than a one-size-fits-all approach.

Material selection is another key aspect. High-performance industries are increasingly using advanced materials such as titanium, nickel alloys, and composites to enhance strength, reduce weight, and improve corrosion resistance. The fabrication company you choose should have experience working with these materials and the right tools to process them without compromising quality.

Flexibility in handling both low-volume custom orders and large-scale production is essential. Whether you need a prototype for testing or mass manufacturing of components, the company should have the capability to scale production while maintaining precision and efficiency.

6. Evaluating Production Efficiency and Delivery Timelines

Project deadlines are critical, and any delay in pipe fabrication can disrupt entire supply chains. Companies that leverage automation, lean manufacturing principles, and digital workflow management can significantly reduce turnaround times while maintaining quality.

Real-time tracking systems allow customers to monitor production progress, ensuring transparency and timely deliveries. An efficient fabricator will also have optimized logistics, from material procurement to final product shipment, minimizing downtime and improving overall workflow.

However, speed should not come at the cost of quality. A reliable fabrication company balances efficiency with thorough quality checks at each stage, ensuring that the final product meets all specifications without defects or inconsistencies.

7. Cost vs. Value: Making the Right Investment

While price is an important consideration, the cheapest option is not always the best choice. Low-cost providers may cut corners on material quality, precision, or compliance, leading to long-term issues and potential rework costs. Instead, focus on value—what you get for your investment.

In 2025, factors influencing pricing include the use of automation, compliance with sustainability regulations, and the complexity of custom orders. Fabrication companies that invest in advanced technology and streamlined operations may have slightly higher costs but offer better efficiency, durability, and reliability.

When comparing service providers, look beyond the initial quote. Consider additional value-added services such as post-fabrication treatments, testing, and long-term support. These factors contribute to a higher return on investment and a more reliable final product.

8. Checking Customer Reviews and Industry Reputation

A company’s reputation in the industry is a strong indicator of its reliability. Reading customer testimonials, online reviews, and industry ratings can provide insights into their work quality and customer service.

Requesting references from past clients allows you to directly assess the company’s professionalism, communication, and ability to meet deadlines. Case studies highlighting successful projects, particularly in your industry, add further credibility.

Strong customer support is another sign of a trustworthy partner. A company that promptly responds to inquiries, provides technical guidance, and ensures after-sales support is more likely to be a dependable long-term fabrication partner.

9. Sustainability and Eco-Friendly Practices

With growing environmental concerns, many industries are prioritizing green manufacturing. A forward-thinking pipe fabrication company should incorporate eco-friendly practices such as using biodegradable lubricants, energy-efficient machinery, and optimized material utilization to reduce waste.

Energy-efficient fabrication equipment minimizes power consumption while maintaining high productivity. Companies that adopt carbon-neutral initiatives, such as recycling excess materials and reducing emissions, contribute to a more sustainable manufacturing ecosystem.

By choosing a company committed to sustainability, you align your project with future-ready practices that meet regulatory standards while reducing environmental impact.

Conclusion:

Selecting the right pipe fabrication company in 2025 requires a careful evaluation of technology, experience, certifications, and customer satisfaction. With advancements in automation, AI, and sustainable manufacturing, the industry is evolving rapidly, making it crucial to choose a partner who stays ahead of these trends.

From material expertise to production efficiency and compliance with industry standards, every factor plays a role in ensuring high-quality fabrication. By prioritizing value, customization, and technological expertise, businesses can make a well-informed decision that leads to long-term success.

If you’re looking for a fabrication company that blends innovation with precision, consider partnering with an industry leader that meets all these criteria. Reach out today to discuss how cutting-edge fabrication solutions can enhance your next project.

Share it!