October 1, 2024

How Custom Pipe Fabrication Saves Money and Boosts Efficiency in Heavy Machinery

Team Pipe Processing

Custom pipe fabrication plays a crucial role in the heavy machinery industry. When machinery relies on complex, high-performance components, having pipes tailored to specific needs can make all the difference. Whether it's for hydraulic systems, exhaust pipes, or cooling mechanisms, custom fabrication ensures a perfect fit, which directly improves equipment performance.

Beyond performance, custom fabrication helps companies manage costs effectively. It allows manufacturers to use only the required materials, reducing waste and avoiding the expense of generic, off-the-shelf parts that may not be fully optimized. By improving the efficiency of both the design and manufacturing process, businesses can save on labor and material costs.

In this article, we'll explore how custom pipe fabrication not only boosts operational efficiency but also leads to significant cost savings over time. From reducing maintenance expenses to extending the life of machinery, custom solutions can be a game-changer for companies in the heavy equipment industry.

Understanding Custom Pipe Fabrication

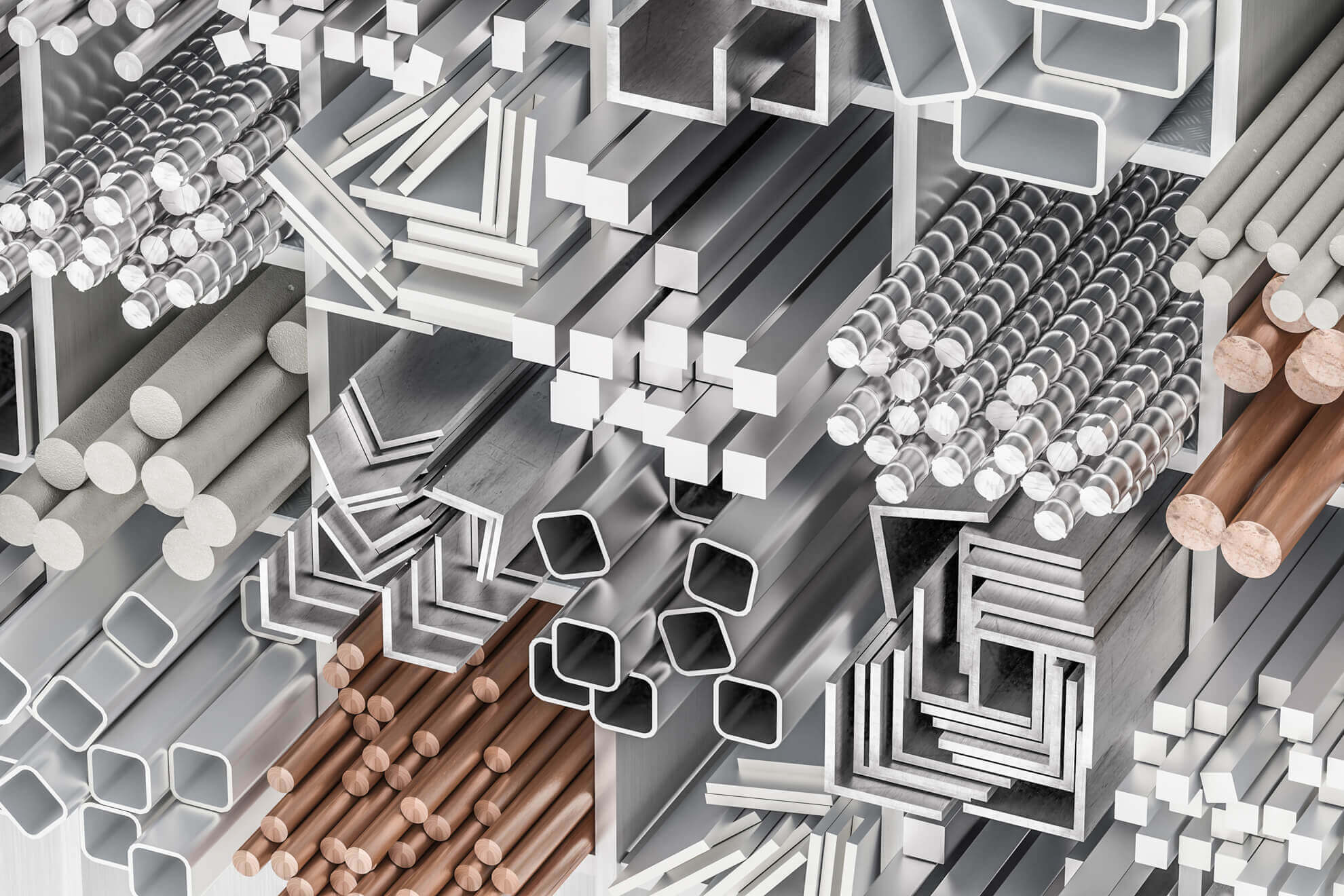

Custom pipe fabrication is a specialized service tailored to create pipes that meet specific dimensions, shapes, and requirements for heavy machinery and industrial applications. Unlike standard pipes, which come in pre-defined sizes and shapes, custom-fabricated pipes are designed to meet exact specifications, which maximizes efficiency and improves the performance of complex machinery systems.

Key Processes in Pipe Fabrication

• Pipe Bending:

Pipe bending is the process of creating curves and angles within pipes to fit specific configurations in machinery layouts. Precision bending is essential in custom fabrication, as it reduces the need for additional joints, improving both durability and fluid flow. Various bending techniques, such as mandrel bending and roll bending, are used based on the pipe material and required angles.

• Welding:

Welding is integral to joining different pipe sections securely. High-quality welds create strong joints that can withstand pressure, temperature, and vibrations, all of which are common in heavy machinery applications. Specialized welding techniques, such as MIG and TIG welding, are often used for precision and durability, as these methods ensure minimal deformation and create cleaner joints.

• Cutting:

Cutting pipes to precise lengths and angles is fundamental to customization. Using advanced tools like plasma cutters, lasers, or CNC machines ensures that each piece is accurately sized to fit seamlessly within the machinery framework. Precise cuts help reduce material waste and ensure that the pipes fit tightly within the system, minimizing the need for adjustments during assembly.

Common Materials Used in Heavy Machinery Applications

Heavy machinery applications demand robust and durable materials. The most common materials include:

• Carbon Steel

Known for its strength and cost-effectiveness, carbon steel is often used in heavy-duty applications where high pressure and load-bearing capabilities are needed.

• Stainless Steel

Stainless steel is favored for its corrosion resistance, especially in applications where pipes are exposed to water, chemicals, or other corrosive elements.

• Aluminum

Lightweight and corrosion-resistant, aluminum is often used in machinery where weight reduction is critical without compromising strength.

• Copper and Alloys

Used for applications requiring high thermal or electrical conductivity, such as in cooling systems, copper alloys are also known for their resistance to corrosion.

Cost Savings Through Custom Pipe Fabrication

• Optimizing Material Selection:

Custom pipe fabrication allows businesses to choose the most suitable materials for their specific heavy machinery needs. By selecting materials that offer the right balance between durability and cost-effectiveness, companies can reduce long-term maintenance costs and avoid overpaying for unnecessary features. This targeted approach maximizes the lifespan of the machinery while keeping the overall costs low.

• Reducing Waste:

One of the primary advantages of custom pipe fabrication is the ability to design pipes that perfectly match the required specifications. This precision minimizes material waste during production. Unlike generic piping solutions, which often require adjustments and lead to material surplus, custom fabrication ensures that every inch of pipe is used efficiently, leading to significant cost reductions.

• Efficiency in Manufacturing:

With custom fabrication, the entire production process becomes more streamlined. By eliminating the need for on-site modifications and using prefabricated parts that fit seamlessly, labor costs are reduced, and production times shorten. This results in quicker project turnarounds and enhanced operational efficiency, making it easier for businesses to stay within budget and meet deadlines.

Enhanced Efficiency in Heavy Machinery Operations

• Tailored Fit for Specific Machinery:

Custom pipe fabrication allows manufacturers to create pipes specifically designed for their machinery, ensuring a precise fit. When components fit perfectly, the risk of leaks, vibration, and wear is reduced, leading to more efficient machinery performance. This precision reduces downtime significantly, allowing equipment to run smoother for longer periods.

• Reduced Maintenance Costs:

Custom-fabricated pipes, made with durable, high-quality materials, are built to withstand the operational demands of heavy machinery. This reduces the frequency of repairs and replacements, cutting down on long-term maintenance costs. With less need for frequent interventions, operations can continue without interruptions, saving both time and money in the long run.

• Improved Flow and Performance:

Custom pipes can be engineered to optimize fluid or air flow within machinery. This improvement boosts overall performance, as it reduces blockages, maintains optimal pressure, and supports smoother operation. Machines that operate with greater efficiency contribute to better productivity and lower energy consumption, enhancing operational effectiveness.

Long-Term Benefits for Heavy Equipment

• Increased Lifespan of Machinery:

Custom components are designed to precisely fit the machinery they are intended for, which increases the overall compatibility and performance of the equipment. This tailored approach ensures that components work harmoniously, reducing unnecessary strain or wear. By improving the durability of these parts, machinery can operate efficiently for a longer period, reducing the need for frequent replacements and extending its operational lifespan. Over time, this helps lower long-term costs while maintaining high productivity levels.

• Sustainability:

One of the significant advantages of custom fabrication is its contribution to sustainability. By creating parts that precisely meet the specifications, manufacturers can reduce material waste, leading to a more eco-friendly production process. This aligns with industry-wide goals to minimize environmental impact, as less waste means fewer resources are needed, and energy consumption during manufacturing is reduced. Sustainability efforts in the heavy equipment industry are crucial as they help conserve natural resources while also lowering operational costs.

Conclusion

Custom pipe fabrication offers a range of benefits, including increased efficiency, cost savings, and tailored solutions to fit specific project needs. Businesses can achieve enhanced flow rates, reduced energy consumption, and longer service life by using custom-designed pipes that match their machinery or project specifications. Additionally, the ability to select high-quality materials, such as corrosion-resistant alloys, ensures safety and durability even in extreme conditions.

Custom fabrication not only reduces maintenance costs but also accelerates project completion through faster turnaround times and flexibility. This results in fewer delays, lower operational downtime, and improved overall performance.

To optimize operations and save costs in the long run, businesses should explore custom pipe fabrication services. Whether for industrial, commercial, or specialized machinery, the advantages of custom solutions cannot be overstated. Reach out to experts in the field to begin tailoring your pipe fabrication needs today.

Share it!