December 1, 2022

How to Find Tube Bender for Your Needs

Team Pipe Processing

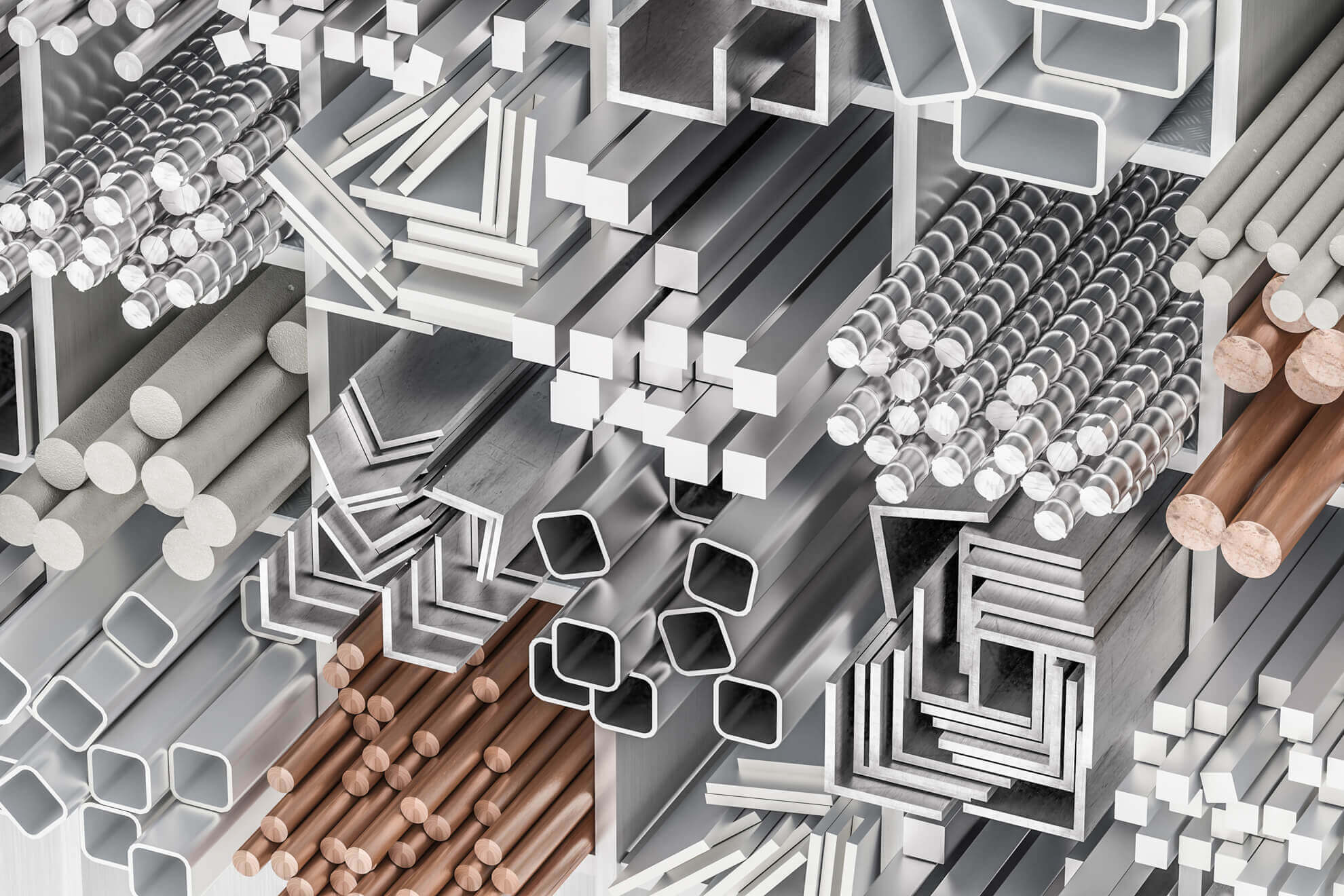

Among the various tools in use in any metal fabrication workshop, one of the main ones is the tube bender. Most individuals who see a bent tube will not think in-depth about it. However, because the alterations are irreversible, the art and science of tube bending need precision, leaving little space for error. There are many kinds of benders, each with unique features and requirements that adhere to uses. The application for which the bender will be used should be well-defined. Analyzing and understanding the bending requirements is crucial. While selecting a bender, there are several other things to consider.

There are many different tube bending machines and options available, including CNC benders, heavy-duty benders, right- and left-tube benders, and specialized benders. Understandably, selecting a tube and pipe bender can seem like a daunting approach with so many alternatives. Making the correct bend depends only on four things: the material, machine, tooling, and lubricant. This is regardless of whether you are working with a tube or pipe and regardless of the bending procedure. There are many other things you may need to consider when selecting the best tube bender.

The information in this post will help you choose the ideal tube bender for your needs.

Factors to Consider While Choosing the right tube bender

If you work in the metalworking sector, you probably understand how important it is to get the proper tools. Therefore, buying a tube bender, consideration of several things is very important. In general, tube benders are divided into groups based on how they operate. Any metalworking project's outcome is influenced by the quality and kind of tools employed. Let us talk about the criteria that will help you choose the best tube bender.

There are four primary categories of benders:

i) Benders with Open Rotary Draws

The most common kind of bender is this one. It is appropriate for bending metal tubes since it bends the tube by pulling it in a curve.

ii) Mandrel Benders

Ball mandrels, which are steel balls, are used in mandrel benders. To bend the tube, a sequence of balls is passed through it while being supported by a curved radius. For large-scale tube bending activities, this equipment is employed.

iii) Roll benders

These benders have a pyramidal structure with three triangularly positioned rollers. To bend the tube at certain angles, it is provided between the rollers.

iv) Ram-style benders

These benders bend tubes according to the radius of the forming die by pushing the die onto the tube with a ram. The ram can be driven manually, hydraulically, or pneumatically.

There are a few more types of benders that are named according to their power sources in addition to these major sorts of benders. These include manual benders, electric benders, NC/CNC electromechanical benders, hydraulic tube benders, pneumatic tube benders, and benders.

You must consider the different types and choose the appropriate tube bender based on your requirements.

1) Examine Your Operational Needs

You must evaluate your requirements to choose the best tube bender for your purposes. The following elements should be considered when determining your operational requirements:

i) Operating Speed

High-speed operations cannot be performed with a manual bender. For high-speed operations, electrical actuators and pneumatic actuators work ideally. Since hydraulic actuators respond effectively to high-load applications, hydraulic benders are appropriate for heavy-duty bending.

ii) Production Batch Size

Mandrel or CNC benders are the best options for heavy-duty production operations. Mandrel bending or CNC bending is preferred for batch bending.

iii) Cost of Operation and Demand

Demand and the budget are two crucial selection criteria. The CNC or electric benders are an excellent investment for increased demands with premium pricing. The manual bender should be considered for slightly less expensive needs.

iv) Machine and Material type

The material being bent must be compatible with the bender. When selecting a suitable bender, one should consider the tube's wall thickness, diameter, material, etc.

2) Examine and research the tools and accessories

Tube benders are made up of a variety of components. Depending on the bender, you can use a multitude of tools, just as with most machines. Use the appropriate accessories for the appropriate machinery for improved performance and efficiency. You can consider several options. Utilize the best equipment and accessories to maximize your tube bending.

3) Different application requirements

The answer to this question can be difficult because there are so many requirements to consider. One could concentrate on the following queries:

• Material that will be bent

• Maximum and minimum tube sizes.

• Part shapes

• Wall thickness of the forthcoming tube

• The required bend's center line radius (CLR)

• Tube's dimensions before it is bent

Other crucial elements that must be considered:

• Is the bender ideal for the requirements of my application?

• Does the material meet my needs for machining perfectly?

• Where can we acquire the highest quality at the lowest price?

• Should we prioritize flexibility or strength? or both?

• How should the tools be cleaned and maintained?

4) Volume

The kind of bending projects one takes on will determine this. Mentioned below are the most essential things to consider:

• How many pieces must be bent in an hour?

• How long the machine would be run for

• How frequently the tooling is changed

• how many times it would run each day or month.

5) Price

Though most owners of metalworking facilities focus on high value at cheap investment, it is insufficient. You must compare the advantages and return on investment that each brand offers because prices for a particular type of tube bending machine occasionally vary across brands.

6) Quality

Making the wrong choice would be costly because tube bending equipment is an investment that must be made just once. The quality of the machine being utilized would decide the quality of the bends.

Final Words

Any machine, including tube benders, requires an investment. When making these decisions, it is important to think about the long-term in mind. What plans do you have? How much expansion are you expecting? All these tube-bending decision-making criteria are important, but the tool must still be appropriate for the task at hand.

Even if you currently only handle smaller tasks, it is a good idea to use your resources to choose tube benders that can manage larger jobs in the future. You should think about and consider your alternatives carefully before choosing the tube bender that will best serve your business's demands. You can choose from the different types of benders with the help of factors and criteria described above, ensuring that it will benefit your business and provide you with the results that you want.

Share it!