October 1, 2023

Innovations in Agricultural Machinery: The Role of Tube Bending

Team Pipe Processing

Agricultural machinery, the backbone of modern farming, stands as a testament to human ingenuity in harnessing technology to meet the ever-growing demands of our global food supply. In an era where the world's population continues to burgeon, and arable land becomes scarcer, the role of agricultural machinery has never been more pivotal. This marvel of engineering isn't just about tractors plowing fields or combine harvesters reaping vast expanses of crops. It encapsulates a realm of sophisticated equipment, each component meticulously designed and constructed to elevate farming efficiency and yield. In this article, we embark on a journey into the heart of agricultural innovation. We'll explore the myriad ways in which modern farming machinery has evolved, adapted, and redefined the agricultural landscape. However, our focus will be particularly keen on one often-overlooked facet of these innovations: tube bending. Amidst the grandeur of massive combines and precision planters, it's easy to underestimate the humble tube and pipe components that play an indispensable role in these agricultural giants.

These unassuming tubes, meticulously bent to perfection, form the circulatory system of agricultural machinery. They facilitate the flow of vital fluids, such as hydraulic oil and coolant, ensuring the seamless operation of complex mechanical systems. They provide structural support, maintaining the integrity of the machinery even in the harshest working conditions. They are the unsung heroes that help maximize efficiency, minimize downtime, and optimize resource usage.

So, let's embark on this exploration of agricultural machinery, innovation, and the unsung hero of it all: tube bending. Together, we'll gain a newfound appreciation for the intricate artistry behind the scenes, driving the efficiency and productivity of modern farming to new heights.

Why tubular components are crucial in agricultural machinery?

Tubular components are the unsung heroes of agricultural machinery, often overshadowed by the larger and more conspicuous parts of these formidable machines. Yet, they play an absolutely crucial role in the functionality and efficiency of modern farming equipment. In this section, we'll delve into the reasons why tubular components are indispensable in agricultural machinery and explore the multifaceted functions they serve.

Structural Support

Tubular components serve as the backbone of agricultural machinery. These meticulously designed and precision-bent tubes and pipes provide essential structural support, ensuring the stability and integrity of the entire machine. They form the framework upon which all other components are mounted and interconnected. Without this sturdy infrastructure, the machinery would be susceptible to structural weaknesses, which could lead to malfunctions, accidents, and reduced durability.

Imagine, for instance, a combine harvester navigating through uneven terrain or a tractor pulling heavy loads. The stresses and forces experienced during these operations are immense. Tubular components are strategically integrated into the machinery's frame to distribute and absorb these forces, preventing deformations and ensuring the machine's overall stability. They act as the sturdy skeleton that enables these agricultural giants to withstand the rigors of the field.

Fluid Transport

Agricultural machinery relies heavily on the efficient transport of various fluids, such as hydraulic oil, coolant, and fuel. Tubes and pipes are the conduits through which these vital fluids flow. They are designed to handle the demands of high-pressure systems, ensuring that hydraulic functions, like lifting and lowering equipment, work seamlessly.

Moreover, the precise bending and routing of tubes in agricultural machinery are critical for the efficient distribution of fluids. This precision is especially important in implements like planters and sprayers, where the accurate delivery of fertilizers, pesticides, or irrigation water can significantly impact crop health and yield. The intricate network of tubes ensures that these fluids are delivered precisely where needed, minimizing waste and optimizing resource usage.

Hydraulic Systems

Hydraulics are the lifeblood of many agricultural machines. These systems use pressurized fluid to power various functions, such as steering, lifting, and control of attachments. Tubes and pipes form the arteries and veins of hydraulic systems, carrying hydraulic fluid to cylinders and motors that perform these functions.

The role of tube bending in hydraulic systems is particularly critical. Precise bends and angles ensure that hydraulic lines can be routed optimally within the limited space available in modern machinery. This optimization reduces the risk of kinks or damage to the hydraulic lines, ensuring consistent and reliable operation. Additionally, custom tube bending solutions can help tailor hydraulic systems to specific machine requirements, improving efficiency and response times.

In summary, tubular components are the unassuming workhorses that underpin the reliability, functionality, and efficiency of agricultural machinery. They provide structural stability, enable the seamless flow of vital fluids, and play a pivotal role in hydraulic systems. These components, meticulously crafted through the art of tube bending, are the hidden champions ensuring that modern farming equipment can tackle the challenges of the field with precision and prowess.

Tube Bending Techniques

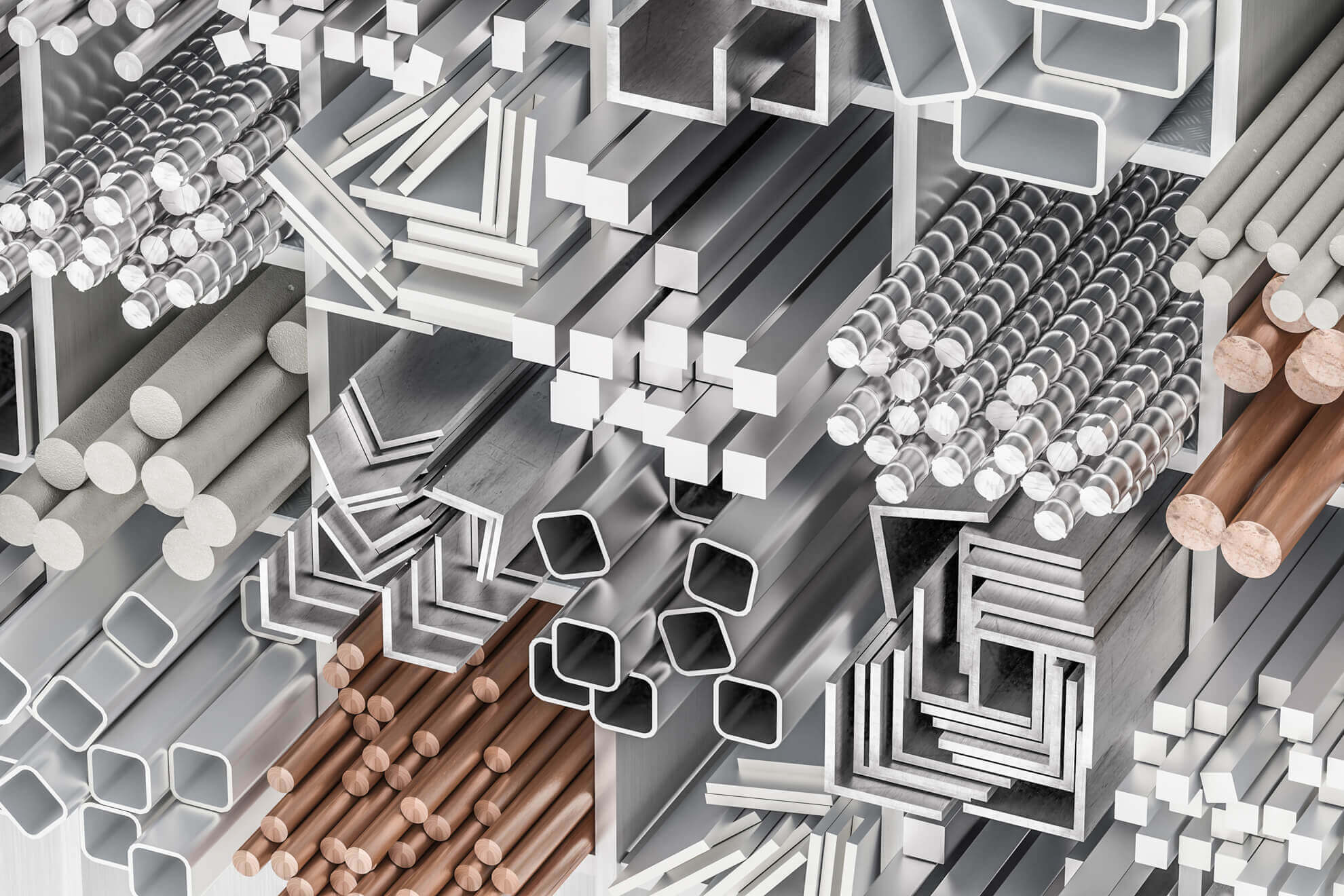

When it comes to the construction of agricultural machinery, the art of tube bending takes center stage. The intricacies of bending tubes to exacting specifications are often overlooked but are vital for the efficient and reliable operation of these powerful machines. Here are a few top Tube bending techniques.

Mandrel Bending

Mandrel bending represents the pinnacle of precision in tube bending. In this technique, a mandrel, a solid rod, is inserted into the tube during the bending process to maintain its shape. This prevents any undesirable wrinkling or deformation, resulting in smooth and uniform bends. Mandrel bending is particularly well-suited for applications in agricultural machinery where hydraulic lines demand optimal flow and pressure consistency. Moreover, it excels in crafting complex shapes required in modern equipment, such as the intricate frame structures and roll cages that provide both structural support and safety.

CNC Bending

CNC (Computer Numerical Control) bending brings automation and pinpoint accuracy to tube bending. With computer-guided machines, CNC bending ensures that every bend is consistent and exact, making it ideal for high-volume manufacturing. It offers exceptional efficiency in design, as complex and intricate tube configurations can be replicated with ease, making it a top choice for adapting to the specific requirements of various agricultural equipment components. While CNC bending machines involve an initial investment, their ability to streamline production and reduce the likelihood of human error makes them a cost-effective choice in the long run, particularly for mass production needs.

Roll Bending

Roll bending is the technique of choice when creating curves and cylinders in tubes for agricultural machinery components. It involves passing the tube through a series of rollers that gradually bend it into the desired shape. This method is particularly useful when agricultural equipment requires components like conveyor belts or frame structures that follow curved or cylindrical paths. Roll bending treats the material gently during the bending process, making it suitable for use with fragile or easily deformable materials, provided they meet the required structural integrity standards.

Compression Bending

Compression bending is all about applying force at specific points on a tube to achieve the desired bend. It's a versatile technique that can be applied to various tube sizes and materials. Achieving precise bends with compression bending requires a delicate balance of factors such as pressure, time, and material considerations. This technique often finds its place when other bending methods might not be the most suitable option. It's particularly common in the creation of custom, one-of-a-kind components for agricultural machinery, where skilled operators can achieve bends tailored to unique needs, ensuring the functionality and efficiency of specialized equipment.

Benefits of Custom Tube Bending for Agricultural Machinery

Custom tube bending is the hidden key to unlocking innovation and optimization in the realm of agricultural machinery. In this section, we'll explore the distinct advantages of employing custom tube bending techniques for the agricultural sector, and we'll journey through real-world examples that vividly illustrate how this precision craft has spurred innovation in farming equipment.

Tailored Efficiency

Custom tube bending allows manufacturers to design and fabricate tubular components that are perfectly tailored to the unique needs of each agricultural machine. Whether it's a specialized pivot point for a tractor's hydraulic system or a precisely contoured tube for a new seeding mechanism, custom bending ensures that every component fits like a glove, optimizing the equipment's efficiency and functionality.

Space Optimization

In the world of agricultural machinery, space is often at a premium. Custom tube bending enables the creation of tubes and pipes that can be routed through tight spaces, making the most of limited room. This is exemplified in the compact design of modern tractors, where custom-bent hydraulic lines ensure that vital components can coexist in harmony, saving both space and weight.

Weight Reduction

Weight is a critical factor in agricultural machinery, affecting fuel efficiency and overall performance. Custom tube bending allows engineers to design components that are not only strong but also lightweight. For instance, custom-bent roll cage structures in utility vehicles provide robust protection without adding unnecessary bulk.

Enhanced Durability

Agricultural machinery operates in some of the harshest environments imaginable. Custom tube bending ensures that components are constructed to withstand these conditions, enhancing their durability and longevity. This is evident in the rugged yet precisely crafted tubing used in the chassis of heavy-duty combine harvesters, which endure the rigors of constant vibration and heavy loads.

Real-World Examples of Innovation through Custom Tube Bending

Precision Seed Delivery

In modern precision agriculture, the accurate placement of seeds is paramount. Custom tube bending techniques have been instrumental in creating specialized seed delivery systems for planters. These systems use precisely bent tubes to transport seeds from the hopper to the soil at a controlled depth, optimizing planting density and maximizing crop yield.

Hydraulic Articulation

Many agricultural machines, such as front-end loaders and forklifts, rely on hydraulic articulation for precise control. Custom tube bending has allowed for the creation of bespoke hydraulic lines that facilitate smooth and responsive movements.

Conclusion

In conclusion, custom tube bending stands as an unsung hero in the world of agricultural machinery. Its ability to tailor components to precise specifications brings a myriad of benefits, from increased efficiency and space optimization to weight reduction and enhanced durability. Real-world examples highlight how custom tube bending has sparked innovation in farming equipment, revolutionizing seed delivery, hydraulic articulation, and implementation design. As agricultural technology continues to advance, custom tube bending will remain an indispensable tool, ensuring that the machinery driving global food production operates at peak performance, contributing to the sustainability and productivity of modern farming.

Share it!