June 1, 2024

Reduce Costs in Pipe Bending: 5 Ways to Save on Material and Manufacturing

Team Pipe Processing

In today's competitive manufacturing landscape, cost efficiency is paramount. Pipe bending, a critical process in various industries, can significantly impact overall production expenses. Whether it's for plumbing, automotive, or construction applications, minimizing costs while maintaining quality and precision is essential for staying ahead.

In this blog, we discussed the five key strategies that can help you reduce costs in pipe bending without compromising on performance. From selecting the right materials to optimizing design and utilizing advanced technologies, these tips will guide you toward a more efficient and cost-effective pipe bending process. Implementing these strategies not only lowers expenses but also enhances productivity and profitability, ensuring your operations remain competitive in a dynamic market.

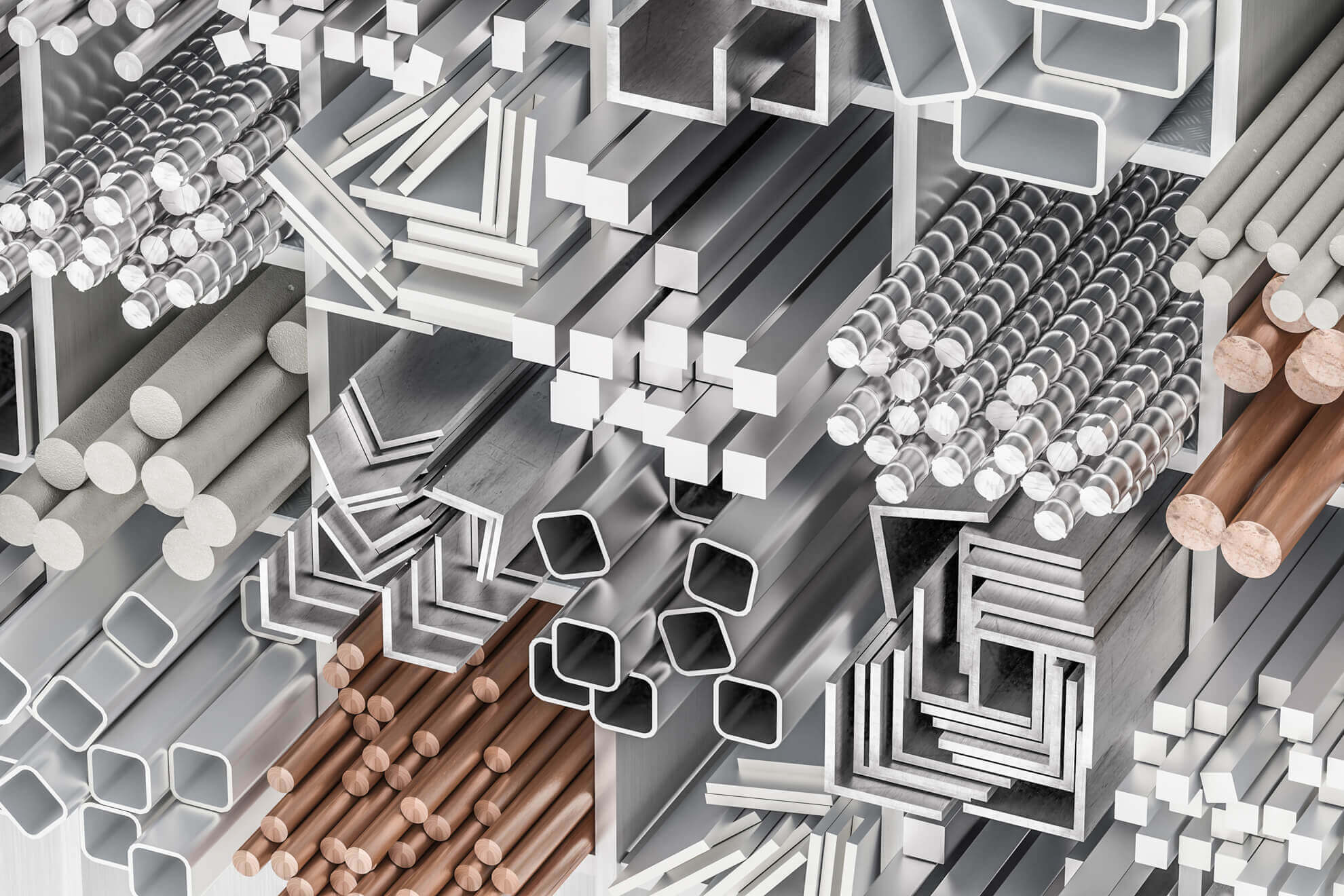

Choosing the Right Material

Selecting the right materials is crucial for any project's success, impacting both quality and cost. Cost-effective material choices can significantly reduce expenses while maintaining the desired performance and durability. Understanding the balance between quality and cost is essential for optimizing your budget.

• Define Project Requirements

Clearly outline the functional, aesthetic, and durability requirements of your project. Knowing exactly what you need helps in selecting materials that meet these criteria without unnecessary expenditures.

• Evaluate Material Options

Compare different materials based on their cost, availability, and suitability for your project. Consider factors like lifespan, maintenance needs, and environmental impact to ensure long-term cost efficiency.

• Consult Local Regulations

Ensure that the materials you choose comply with local building codes and regulations. This can prevent costly legal issues and modifications later on.

• Consider Substitutes

Look for more readily available and cheaper alternatives that can perform similarly to more expensive options. For example, using recycled materials or locally sourced options can often reduce costs without compromising quality.

• Budget Planning

Allocate a portion of your budget specifically for materials and stick to it. This helps in making informed choices and avoiding overspending.

Optimizing Design for Manufacturability

Designing for manufacturability (DFM) can significantly reduce complexity and costs.

Here’s how you can optimize your design:

• Simplify Designs

Avoid overly complex designs that require intricate bending processes. Simple designs are easier and cheaper to produce. By reducing the number of parts and simplifying the geometry, you can minimize the potential for errors and reduce production time.

• Standardize Bending Radii

Using common bending radii across different parts can minimize tooling costs and reduce setup times. This standardization not only simplifies the manufacturing process but also facilitates easier assembly and integration of parts.

• Collaborate with Manufacturers

Work closely with manufacturers during the design phase to ensure that your designs are practical and cost-effective to produce. Their expertise can provide valuable insights into reducing manufacturing complexity and costs. Early collaboration can help identify potential issues and optimize designs for the available manufacturing capabilities.

• Use Standard Materials and Components

Incorporating standard materials and components in your design can lead to significant cost savings. Standard parts are often cheaper and more readily available, reducing lead times and inventory costs. Additionally, using common materials can simplify the supply chain and improve production efficiency.

• Optimize Production Techniques

Evaluate and choose the most efficient production techniques for your design. Advanced manufacturing technologies, such as CNC bending and automated systems, can enhance precision and reduce material waste. Regularly reviewing and updating your production techniques ensures that you are utilizing the most cost-effective methods available.

• Eliminate Unnecessary Features

Streamline your design by eliminating features that do not add value or functionality. Reducing unnecessary elements can lower production costs and simplify the manufacturing process. Focus on the essential features that meet your project's requirements.

• Conduct Design Reviews and Simulations

Conducting thorough design reviews and simulations can help identify potential manufacturing issues before production begins. Use simulation software to test different design scenarios and optimize for manufacturability. This proactive approach can save time and money by preventing costly redesigns and production delays.

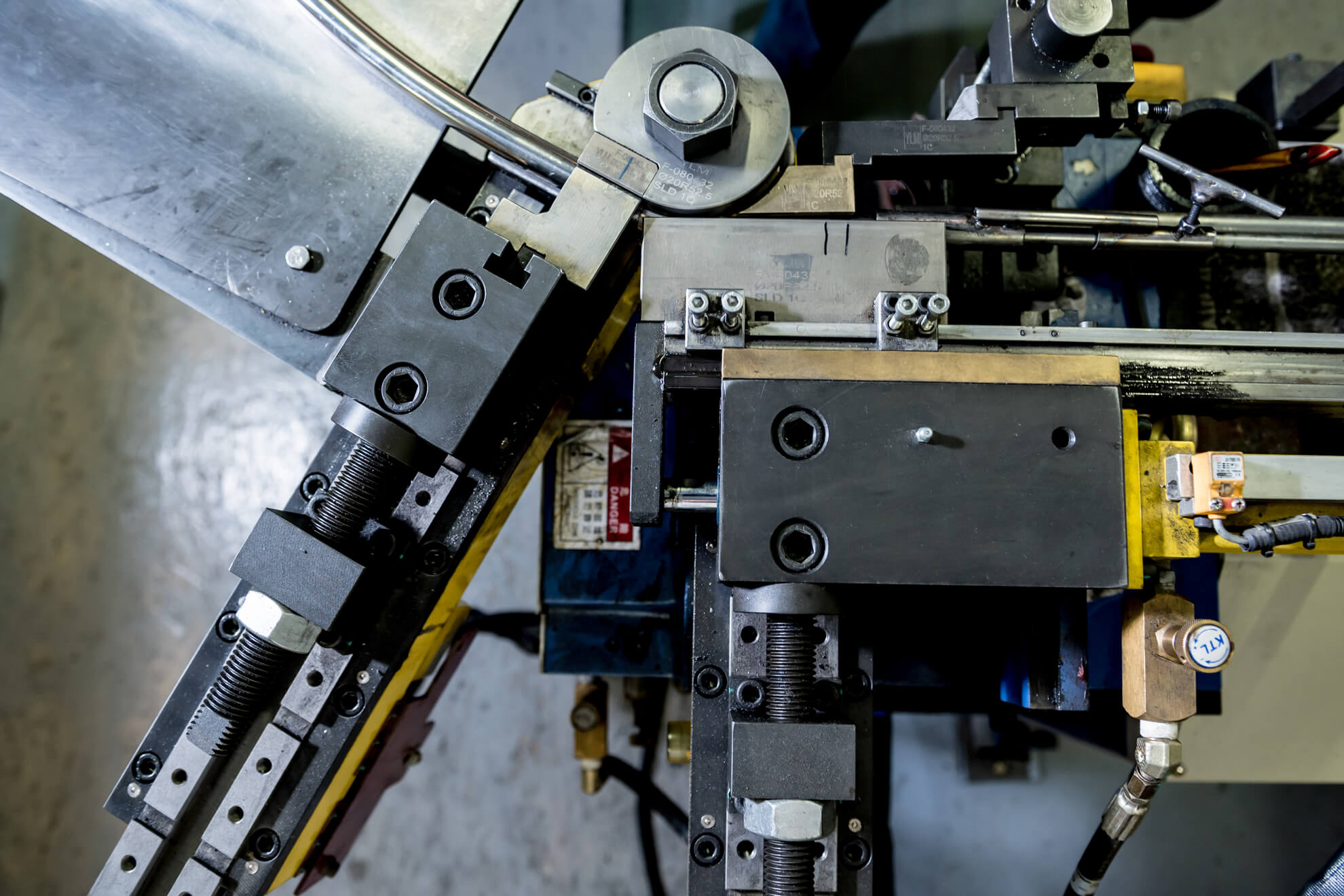

Improving Manufacturing Processes

Streamlining the manufacturing process is essential for minimizing waste and maximizing efficiency.

Here are additional strategies to enhance your manufacturing processes:

• Invest in Employee Training and Development

Well-trained employees are key assets in any manufacturing environment. Providing comprehensive training programs ensures that your workforce understands the latest techniques, safety protocols, and equipment operation. Continuous skill development empowers employees to perform their tasks more efficiently, resulting in higher productivity and fewer errors.

• Implement Lean Manufacturing Principles

Adopting lean manufacturing principles, such as 5S methodology, value stream mapping, and Just-in-Time (JIT) inventory management, can significantly improve operational efficiency. These principles focus on eliminating waste, optimizing workflows, and enhancing overall productivity. By streamlining operations and reducing non-value-added activities, lean manufacturing minimizes costs and enhances customer satisfaction.

• Embrace Sustainable Practices

Integrating sustainable practices into your manufacturing processes reduces environmental impact and improves operational efficiency. Implementing energy-efficient technologies, recycling initiatives, and waste reduction programs can lower production costs and enhance your company's reputation as a socially responsible organization.

• Foster a Culture of Innovation

Encourage innovation and creativity among your workforce by providing opportunities for idea generation and collaboration. Establishing a culture that values continuous improvement and innovation empowers employees to identify and implement process enhancements. By fostering a culture of innovation, you can stay ahead of the competition and drive long-term success.

Pipe Processing Technical Institute is committed to improving safety, quality, cost, and production control for our customers. (our facilities)

Negotiating with Suppliers

Effective negotiation with suppliers is a multifaceted process that requires careful consideration of various factors beyond just pricing.

Here are additional strategies to enhance your negotiation efforts:

• Emphasize Quality and Reliability

While price negotiation is crucial, it's equally important to prioritize quality and reliability. Emphasize the importance of high-quality materials and timely delivery in your negotiations. Suppliers who can consistently meet your quality standards and delivery timelines are invaluable partners in ensuring the success of your manufacturing operations.

• Explore Value-Added Services

In addition to competitive pricing, seek out suppliers who offer value-added services that align with your business needs. These services may include inventory management, just-in-time delivery, or technical support. By leveraging these services, you can further optimize your supply chain, reduce administrative overhead, and improve overall efficiency.

• Seek Flexible Payment Terms

Negotiate flexible payment terms with your suppliers to improve cash flow and mitigate financial risks. Options such as extended payment terms, milestone-based payments, or early payment discounts can provide financial flexibility while maintaining a positive relationship with your suppliers.

• Foster Open Communication

Establish open and transparent communication channels with your suppliers to facilitate effective negotiation and problem-solving. Regularly communicate your expectations, concerns, and feedback to ensure alignment and address any issues proactively. Building trust through open communication lays the foundation for long-term partnerships built on mutual respect and collaboration.

Reducing Labor Costs

Reducing labor costs requires a multifaceted approach that encompasses various aspects of workforce management.

Here are additional strategies to further optimize labor expenses:

• Embrace Cross-Training and Multi skilling

Encourage cross-training and multiskilling initiatives within your workforce to enhance flexibility and productivity. By equipping employees with diverse skill sets, you can adapt to fluctuating production demands more effectively, minimize downtime, and reduce the need for additional labor resources.

• Utilize Performance Incentives

Implement performance-based incentives to incentivize productivity and quality improvements among your workforce. Rewarding employees for achieving performance targets or exceeding production goals can foster a culture of continuous improvement and drive cost-effective outcomes.

• Leverage Technology for Automation

Invest in automation technologies and robotics to streamline repetitive tasks and minimize reliance on manual labor. Automated systems can increase production efficiency, reduce error rates, and ultimately lower labor costs by optimizing resource utilization and reducing the need for manual intervention.

• Implement Flexible Work Arrangements

Explore flexible work arrangements such as telecommuting, flexible scheduling, or compressed workweeks to accommodate employee preferences while maximizing productivity. Flexible arrangements can help reduce absenteeism, improve employee morale, and potentially lower overhead costs associated with maintaining physical workspaces.

• Regularly Review and Optimize Processes

Continuously evaluate and optimize your manufacturing processes to identify opportunities for labor efficiency improvements. Solicit feedback from frontline workers, monitor key performance indicators, and implement process enhancements to streamline workflows, eliminate bottlenecks, and maximize labor productivity.

By incorporating these additional strategies into your labor cost management efforts, you can further enhance operational efficiency, drive cost savings, and maintain a competitive edge in today's dynamic manufacturing landscape.

Conclusion

By focusing on these five strategies—choosing the right material, optimizing design for manufacturability, improving manufacturing processes, negotiating with suppliers, and reducing labor costs—you can achieve significant savings in your pipe-bending projects. Continuous evaluation and adaptation are essential to maintaining cost-efficiency and ensuring long-term success.

Share it!