July 1, 2024

Top 10 Benefits of Precision Pipe Bending for the Automotive Industry

Team Pipe Processing

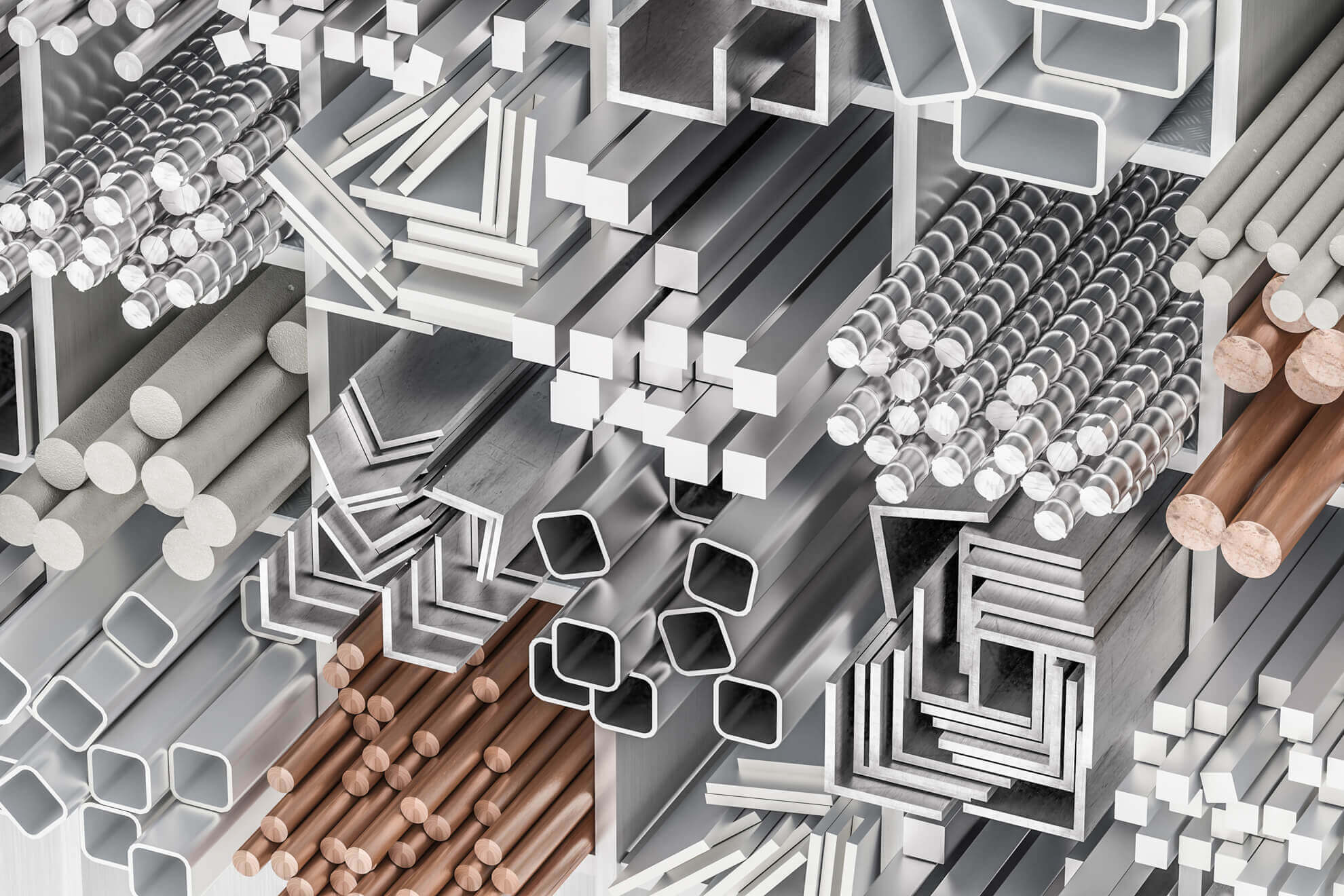

In the fast-evolving automotive industry, precision and efficiency are paramount. Every component, from the engine to the exhaust system, plays a crucial role in ensuring the vehicle performs optimally. One often overlooked yet vital aspect of automotive manufacturing is pipe bending. This process involves shaping pipes and tubes to fit specific design and functional requirements within a vehicle.

Precision pipe bending is essential in automotive manufacturing for several reasons. Firstly, it allows for the creation of complex shapes and pathways necessary to fit modern vehicles' intricate designs. This is particularly important as automotive engineers strive to optimize space, reduce weight, and improve the aerodynamics of their designs. A well-bent pipe or tube ensures seamless integration into the vehicle’s architecture, contributing to its overall efficiency and performance.

Secondly, precision pipe bending enhances the durability and reliability of automotive components. Creating smooth bends with minimal stress points significantly reduces the risk of fatigue and failure. This not only extends the lifespan of the components but also ensures the safety and dependability of the vehicle as a whole.

1. Improved Fluid and Gas Flow

Precision pipe bending optimizes automotive engine performance by ensuring the smooth, unobstructed flow of fluids and gases, which is essential for systems like fuel lines, coolant systems, and exhaust systems. Smooth bends minimize turbulence and resistance, enhancing engine performance, fuel efficiency, and reducing emissions.

Additionally, precision bending reduces the risk of leaks and blockages, maintaining engine reliability and longevity, and preventing costly repairs. This not only provides end-users with dependable vehicles but also enhances the manufacturer's reputation for quality and efficiency. At Pipe PTI, our expertise in precision pipe bending ensures superior performance and efficiency with every bend.

2. Increased Durability and Longevity

In the automotive industry, the durability and longevity of vehicle components are paramount. Precision pipe bending significantly contributes to these attributes by evenly distributing stress along the bend, preventing localized stress concentrations that can lead to fatigue and failure.

This reduces the need for additional joints and connectors, which are common weak points, thus minimizing the risk of leaks and breakage. By creating seamless, continuous pathways, precision bending enhances the strength and durability of components, allowing them to withstand the rigors of everyday use and harsh conditions.

For automotive manufacturers, this translates into lower warranty claims, fewer recalls, and a stronger reputation for reliability. At Pipe PTI, our advanced bending techniques ensure that every bend enhances component strength and durability, providing long-lasting, reliable parts.

3. Weight Reduction

Precision bending allows automotive manufacturers to use lighter materials without compromising strength, contributing to overall vehicle weight reduction. By enabling precise and efficient designs, manufacturers can opt for thinner, lighter materials while maintaining the structural integrity of the components. This reduction in weight enhances vehicle performance by improving fuel efficiency, handling, and acceleration. Lighter vehicles also produce fewer emissions, making them more environmentally friendly.

4. Space Optimization

Precision bends enable better utilization of available space within the engine compartment, allowing for more compact and efficient designs. Automotive engineers often face the challenge of fitting numerous components into a limited space. Precision pipe bending helps by creating complex shapes and pathways that maximize the use of available space. This space optimization is crucial for modern vehicles, where every inch of the engine compartment is valuable.

By allowing for more compact designs, precision bending contributes to overall vehicle efficiency and performance, helping manufacturers meet the increasing demands for space-efficient and high-performing vehicles.

5. Cost Savings

Precision bending minimizes material wastage and reduces overall manufacturing costs, leading to significant cost savings for manufacturers. By creating accurate and consistent bends, precision bending reduces the need for additional fittings and connectors, which can add to material and labor costs.

Furthermore, efficient use of materials means less scrap and waste, contributing to a more sustainable manufacturing process. These cost savings can be passed on to consumers in the form of more affordable vehicles or reinvested into further innovations. At Pipe PTI, our advanced bending techniques ensure that manufacturers can achieve these efficiencies, ultimately improving their bottom line.

Blog: Reduce Costs in Pipe Bending: 5 Ways to Save on Material and Manufacturing

6. Customization and Flexibility

Precision bending offers the ability to create custom bends that meet specific design requirements, providing greater flexibility in automotive design and engineering. This customization is essential for manufacturers who need to differentiate their products and meet unique customer needs. Whether it's a bespoke exhaust system or specialized fuel lines, precision bending allows for tailored solutions that enhance the functionality and aesthetics of the vehicle.

Pipe PTI's commitment to precision and quality ensures that every custom bend is executed flawlessly, enabling manufacturers to achieve their design goals and innovate with confidence.

7. Improved Aesthetics

Precision bending can produce smoother, more visually appealing lines and shapes, enhancing the overall aesthetics of the vehicle. A well-designed vehicle not only performs well but also looks great, and the visual appeal can significantly influence consumer preferences. Smooth and precise bends contribute to a sleek and professional appearance, whether visible components like exhaust systems or hidden ones like internal tubing. This improved aesthetics can be a key selling point, adding to the perceived value and desirability of the vehicle.

8. Faster Production Times

Advanced bending techniques streamline production processes, reducing lead times and speeding up time-to-market. Precision bending equipment and techniques allow for quick and accurate bends, minimizing the need for rework and adjustments. This efficiency in the manufacturing process means that parts can be produced and assembled faster, helping manufacturers meet tight deadlines and respond quickly to market demands. Faster production times also mean quicker delivery to customers, enhancing overall customer satisfaction.

9. Enhanced Safety

Precision bends ensure the structural integrity of components, reducing the risk of failure and enhancing overall vehicle safety. In the automotive industry, safety is non-negotiable, and the quality of components plays a critical role in ensuring vehicle safety. Precision bending reduces the likelihood of weak points and potential failure areas, providing robust and reliable components that can withstand high pressures and stresses. This enhanced safety not only protects the vehicle's occupants but also boosts the manufacturer's reputation for producing safe and reliable vehicles.

10. Compliance with Industry Standards

Precision bending helps manufacturers meet stringent industry standards and regulations, ensuring compliance and avoiding penalties. Automotive components must adhere to various safety, environmental, and quality standards, which can vary by region and application. Precision bending ensures that components meet these standards by producing accurate and consistent bends that comply with regulatory requirements. This compliance is crucial for manufacturers to avoid costly fines, recalls, and reputational damage.

Conclusion

Precision pipe bending offers numerous benefits for the automotive industry, including improved fluid and gas flow, increased durability and longevity, weight reduction, space optimization, cost savings, customization and flexibility, improved aesthetics, faster production times, enhanced safety, and compliance with industry standards. Each of these benefits contributes to the overall performance, efficiency, and reliability of automotive components, helping manufacturers meet the demands of modern vehicle design and production.

At Pipe PTI, we are dedicated to providing precision pipe bending solutions that deliver these benefits, ensuring that our clients receive the highest quality components to enhance their products and maintain their competitive edge in the market. Contact us today to learn more about how our precision bending services can help you achieve your manufacturing goals.

Blog: 9 Reasons Why Professional Tube Bending Is Essential for Industrial Projects

Share it!