January 1, 2024

How Tube Bending Shapes the Future of the Agriculture Industry

Team Pipe Processing

Step into the realm of tube bending, where precision converges with innovation, reshaping the future of agriculture. In the ever-evolving landscape of industries, some processes emerge as silent champions working behind the scenes. Tube bending, a seemingly straightforward yet profoundly influential technique, plays the role of such a hero, weaving its impact through diverse sectors and reaching the core of agriculture.

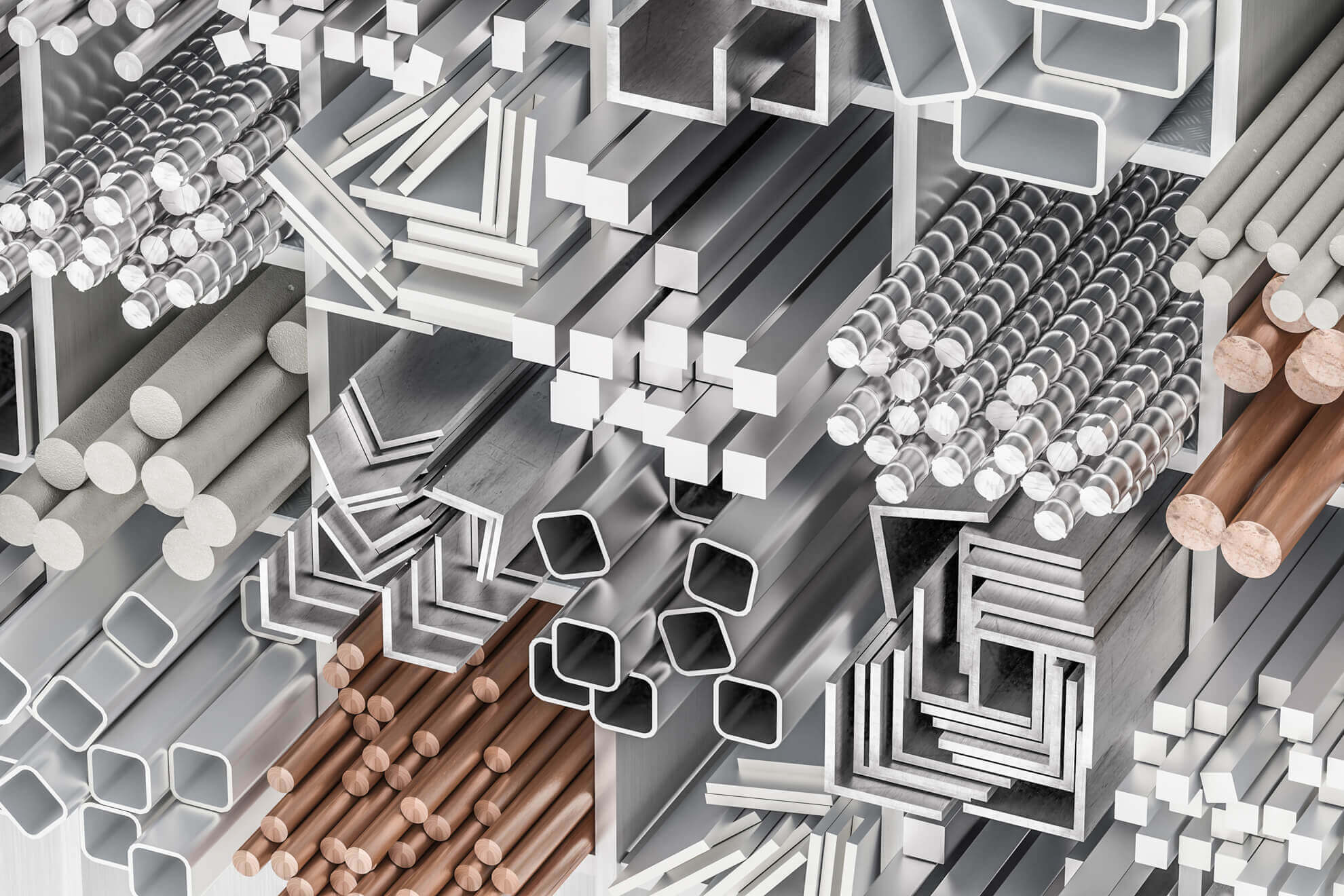

Tube bending, at its core, is a transformative process that goes far beyond shaping metal. It is the silent force driving the curves and contours of modern machinery, providing the structural backbone for innovation. While it plays a crucial role in diverse industries, our focus today is on its profound impact on agriculture.

In this exploration, we delve into the nuances of tube bending, unraveling its significance in the agricultural realm. From the basic principles that shape the bends to the choice of materials ensuring longevity, we journey through the fields of crop management, irrigation systems, and the robust structures supporting the backbone of agricultural machinery.

Understanding Tube Bending in Agriculture

At the heart of manufacturing, tube bending stands as a transformative art. The seemingly ordinary metal tube undergoes a metamorphosis, becoming a customized masterpiece poised to fulfill a crucial role in agriculture. Think of it as sculpting with metal – a fusion of precision and expertise that shapes the functional beauty supporting various industries, especially in the realm of agriculture. Envision a metal tube, initially unremarkable, now taking on graceful arcs and bends seamlessly integrated into the design of agricultural machinery. Tube bending is the wizardry behind this metamorphosis, an invisible force crafting the frames of plows and the intricate arms of crop management tools, transforming raw materials into precision-engineered components.

Delving into the basics reveals that the principles of tube bending are deeply rooted in the science of material deformation, forming the backbone of machinery design in agriculture. This intricate dance of precision and control involves manipulating metal tubes with care to achieve specific angles and radii. Whether fashioning a curved component for a harvesting machine or structuring an irrigation system, the methods of tube bending ensure that every curve serves a purpose.

Mandrels and dies take center stage in this manufacturing drama, preventing tube collapse during bending and guiding the tube to its final form, becoming architects of efficiency in the agricultural playbook. The choice of materials further adds nuance to this art, resembling the selection of a perfect canvas for an artist.

In agriculture, where environmental demands are high, materials play a paramount role – from providing resilience in crop management tools to corrosion resistance in irrigation systems, ensuring that each bend can withstand the rigors of the field. As we journey deeper into the world of tube bending, these basics emerge as the foundation upon which the agricultural landscape is shaped – a dance of science and craftsmanship where each bend narrates a story of innovation, efficiency, and reliability in the machinery sustaining our global harvests.

Applications in Agricultural Machinery

In the vast tapestry of agriculture, tube bending emerges as a cornerstone in the design of crop management equipment, contributing to the efficiency and precision needed for modern farming practices. Imagine the graceful arms of a precision seeder or the precisely curved elements of a cultivating implement – each owes its form to the careful dance of tube bending. The role here is transformative; it's about turning rigid metal into the flexible anatomy of machinery that navigates the intricacies of cultivating and nurturing crops.

Here are the key applications in agriculture machinery.

Crop Management

Tube bending takes center stage in the design of crop management equipment, playing a pivotal role in the optimization of farming practices. Picture the curved arms of a precision seeder, artfully shaped by tube bending to ensure accurate and efficient seed placement. This isn't just about aesthetics; it's a functional transformation. The bends in plow structures, for instance, are strategically designed to enhance soil penetration and furrow creation, embodying the precision required for modern agriculture. Real-world examples include the arms of precision planters and the frames of adjustable row cultivators, where tube bending becomes a silent collaborator in the daily tasks of farmers. In the hands of the user, it's not merely a manufacturing technique; it's a tool that fosters the seamless choreography of crop management, reflecting the user-friendly face of tube bending in the fields.

Irrigation Systems

Step into the domain of effective irrigation systems, where the precision of tube bending plays a pivotal role in accurately distributing water throughout agricultural landscapes. Imagine a network of tubes, each bend strategically crafted to ensure water reaches every corner of the field. Tube bending, in this context, is the architect of water efficiency. Precision bending enhances the performance of irrigation systems by allowing for tailored designs that adapt to the topography of the land. It's about creating a symphony of bends that harmonize with the needs of each crop, ensuring optimal water distribution. From the gentle curves guiding water along rows of crops to the intricate twists managing water flow in uneven terrain, tube bending transforms irrigation into a user-friendly, resource-efficient dance that sustains the life of the fields.

Equipment Frames and Structures

The significance of durable structures cannot be emphasized enough. Tube bending becomes the backbone of these structures, ensuring they withstand the demanding conditions of the field. Consider the frames of tractors or the structures supporting heavy-duty harvesting equipment; each bend is a testament to the reliability tube bending brings to the agricultural arena. These structures aren't just about strength; they embody the user-focused design necessary for ease of operation. The frames of equipment, shaped by tube bending, provide the necessary support without compromising on maneuverability. It's a marriage of strength and user-friendly design, where tube bending forms the skeletal framework that supports the daily tasks of farmers, reflecting the artistry and resilience required in the agricultural landscape.

Advantages of Tube Bending in the Agriculture industry

Strength and Durability

When it comes to the demanding world of agriculture, the strength and durability of equipment are non-negotiable, and this is where tube bending steps into the spotlight as a game-changer. Picture the implements in the field – plows carving through the soil, cultivators navigating diverse terrains, and frames supporting the weight of heavy machinery. Tube bending, with its precision-engineered curves, brings robustness to these components that withstands the challenges of the agricultural landscape.

Crafting Resilience: The Tube Bending Advantage

Tube bending is not just about creating pleasing forms; it's about fortifying the very essence of agricultural equipment. The bends and curves aren't arbitrary; they're strategic reinforcements. For instance, in the arms of a plow, tube bending ensures that the structure can endure the forces encountered during soil preparation, providing the necessary strength to power through tough conditions. This resilience translates into equipment that stands the test of time, forging a bond of trust between the farmer and their tools.

Longevity in the Fields: A Testimony to Tube Bending Precision

The impact on the longevity and reliability of agricultural equipment is profound. Tubes, expertly bent to precise angles and radii, create components that don't just meet standards but exceed them. Consider the frames of tractors or the structures supporting harvesters – these aren't just tubes; they are meticulously shaped elements designed to resist wear and tear. Tube bending transforms mere components into pillars of reliability, extending the lifespan of agricultural machinery. In the hands of the user, it's not just about bending metal; it's about investing in equipment that endures, ensuring that each season, the farmer can rely on the strength and durability of their tools to bring the harvest home.

Conclusion

In the expansive landscape of agriculture, tube bending quietly takes on the role of an architect, sculpting the fundamental elements of our sustenance. In the precise coordination of crop management tools and the strategic reinforcement of equipment frames, tube bending emerges as the uncelebrated hero, reshaping metal into a fusion of reliability and innovation. As manufacturers and farmers navigate the evolving landscape, it's an encouragement to explore the boundless possibilities that tube bending offers. It's not just about bending metal; it's an invitation to invest in equipment that embodies strength, resilience, and longevity.

In this intricate partnership between technology and the fields, tube bending becomes a promise, ensuring that each curve tells a story of progress and efficiency. So, let's embrace the artistry of tube bending, a bridge between tradition and innovation, and pave the way for a future where the harvest is not just bountiful but sustainable and shaped by the ingenuity of those who till the land.

Share it!